Ruite is a China based Slurry pump manufacturer.

The

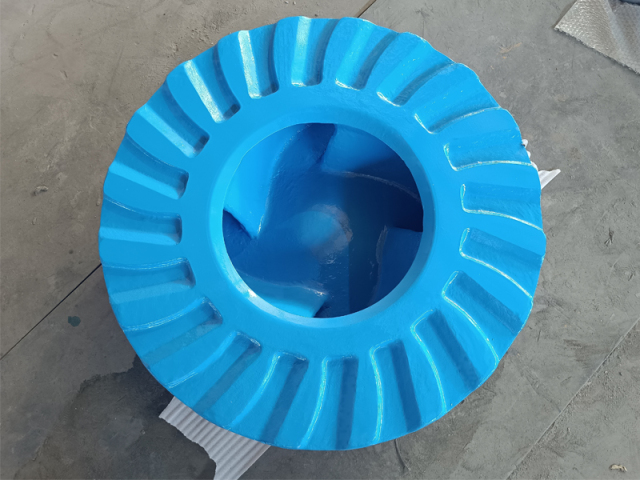

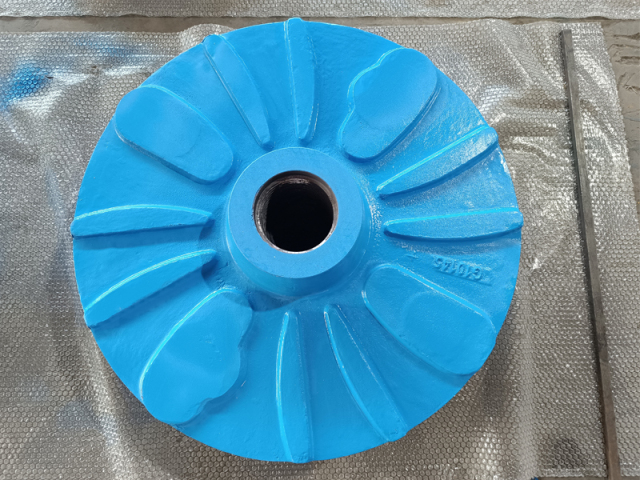

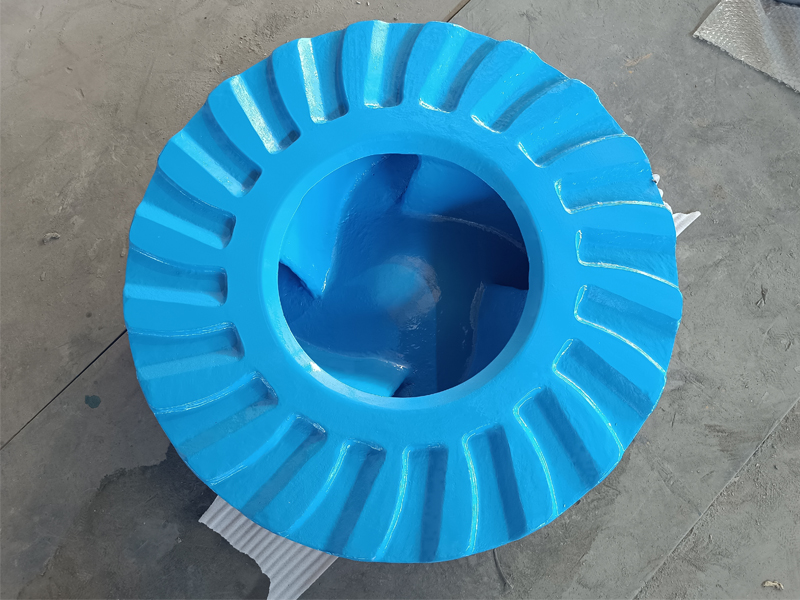

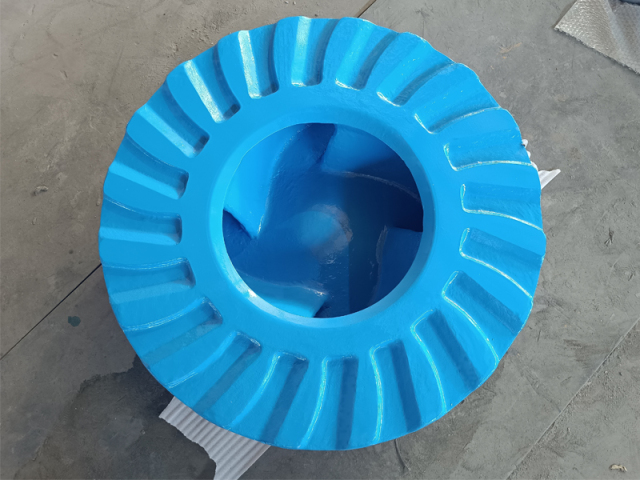

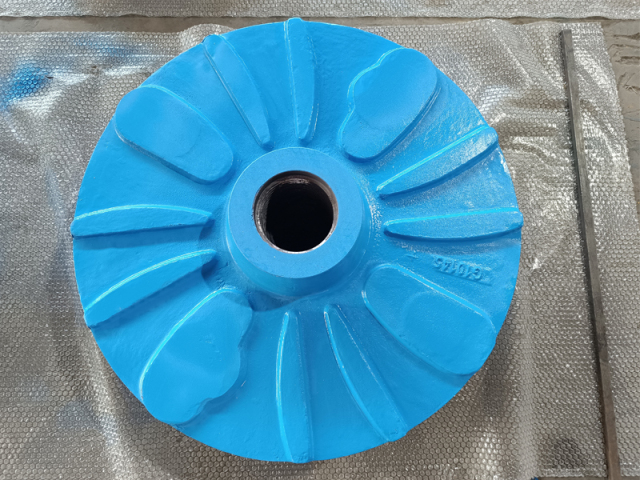

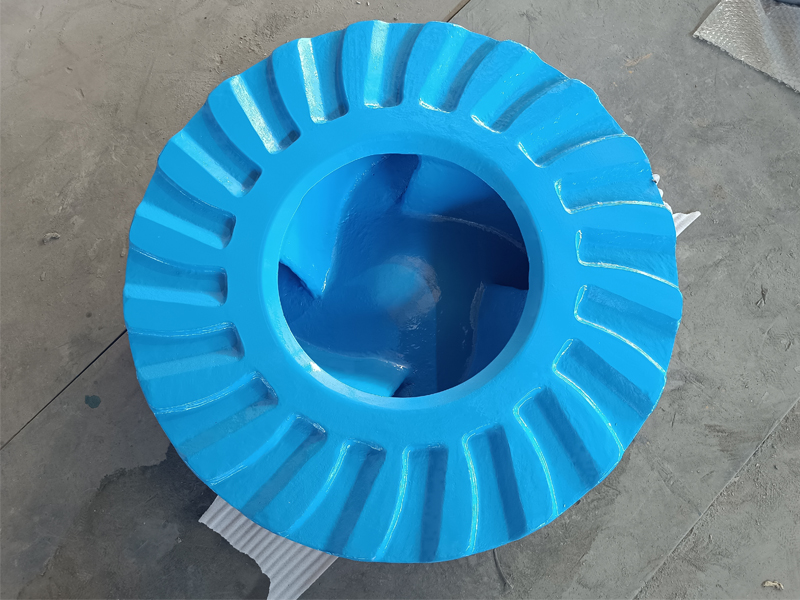

slurry pump impeller play an extremely important role in the operation of centrifugal slurry pump. By rotating, it can help slurry pump meet the needs of the equipment.

The slurry pump impeller is easy to be worn out, so we search for the special materials to prolong the lifespan of impeller, high chrome white iron is one of them, aims at handling the slurries with strong abrasion or sharp particles.

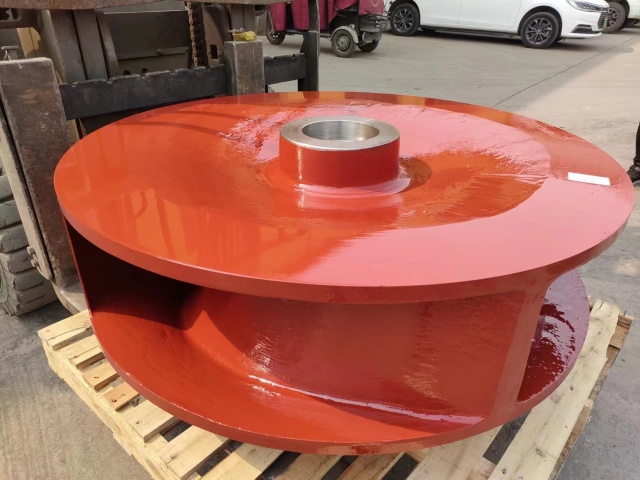

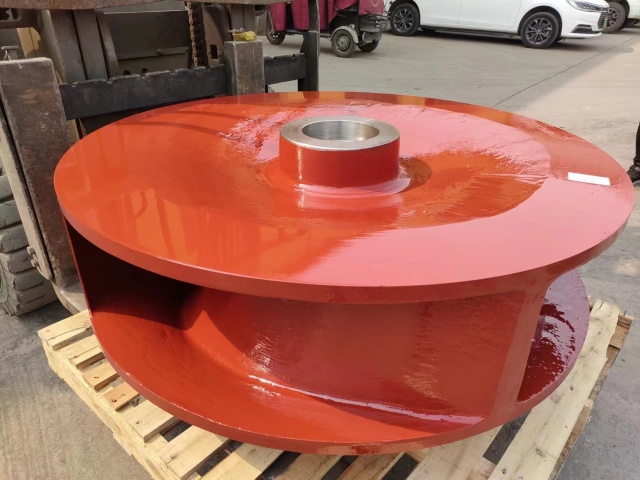

There are main three type of impeller, Open, Semi-open and Closed. So impeller selection to deal with different slurry with solid have different choices. Our engineer will offer you the best solution for slurry handling.

As a China-based slurry pump manufacturer, we provide a broad range of impellers, including froth pump impeller, medium/light duty pump impeller, sump pump impeller sand pump impeller and FGD(flue gas desulfurization) pump impeller or customized impellers.

For now, we can produce our own pump impellers, and also can do some other slurry pump impellers size and material compactly.

The slurry pump parts consists wet parts, sealing parts, bearing assembly, pedestal and other parts.

In slurry pump, Wet Parts means the lining parts which contact with fluid media, usually it includes impeller, volute, frame plate, throat bush. These parts will easily get corroded or abraded when working and should be replaced after a period of use.

Usually the pump parts are made of iron, steel, bronze, brass, aluminum, plastic etc. For Slurry pumps, they are normally made of High chrome alloy, Rubber, polyurethane, and ceramic. High chrome alloy and Rubber are now the main material for the slurry pumps.

For chrome alloy material, the common type is High chrome Alloy, it can be used from pH 5 to 12, and its hardness can be to HRC58, which is a very good choice for slurry handling and transport. But in some conditions, the pH may be lower than 5, then we try A49, it can be lower to pH 4, mostly used in FGD processing.

The Rubber material is widely used in fine slurry conditions and lower pH to 2. There are also many rubber materials for different conditions, such as R08, R26, R55, S02, etc.

The spare and wear parts program from Ruite offers the confidence that you can ensure plant safety and maintain like-new performance.

As a single-source supplier we stand behind every product and component simplifying maintenance and supporting uptime.

Our slurry pump parts are strategically inventoried close to our customers so they can be quickly deployed in times of need.

We work with us.