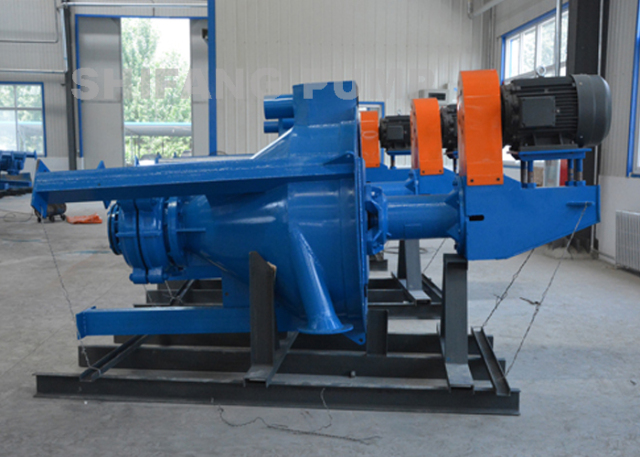

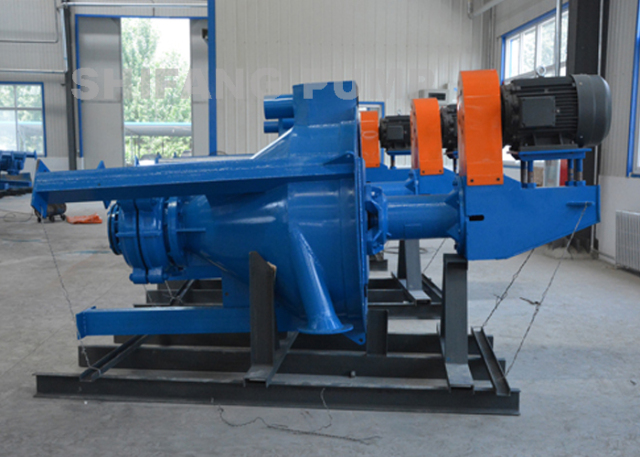

The basic principle of the pump operation is to remove or partially remove the froth before the slurry enters the pumping. Its handling capacity is much higher than that of other types of slurry pump without shaft seal and sealing water. It is a perfect pump for handling frothy pulp.

The structure of pump head is double casing. All wet parts can be supplied in Ni-hard, high chrome alloy iron and pressure-moulded natural or synthetic rubber. The driver end can be exchanged with tsp pumps. The hopper-tank is fabricated with steel plate.

Its inner wall of the tank can be covered with liner according to different medium pumped.

The discharge branch can be positioned at intervals of 45 degrees by request and

oriented to any eight positions to suit installations and applications.

TVF Vertical Froth Slurry Pump Performance Parameters

| Model | Flow rate | Head | Speed | Efficiency | Max solid | Max power | Suctiondiameter | Dischargediameter |

| (L/s) | (m) | (r/min) | (%) | (mm) | (kW) | inch | inch | |

| 50QV-TVF | 1.2-14.2 | 6.2-30.2 | 800-1800 | 20-45 | 35 | 15 | 4 | 2 |

| 75QV-TVF | 3.0-41.5 | 6.5-29.5 | 700-1500 | 20-55 | 38 | 20 | 6 | 3 |

| 100RV-TVF | 3-59 | 6.8-29.2 | 500-1050 | 20-55 | 55 | 40 | 6 | 4 |

| 150SV-TVF | 10-118 | 6.8-25.2 | 350-680 | 20-55 | 63 | 75 | 8 | 6 |

| 200SV-TVF | 64-186 | 5-24.8 | 350-680 | 20-55 | 70 | 110 | 10 | 8 |