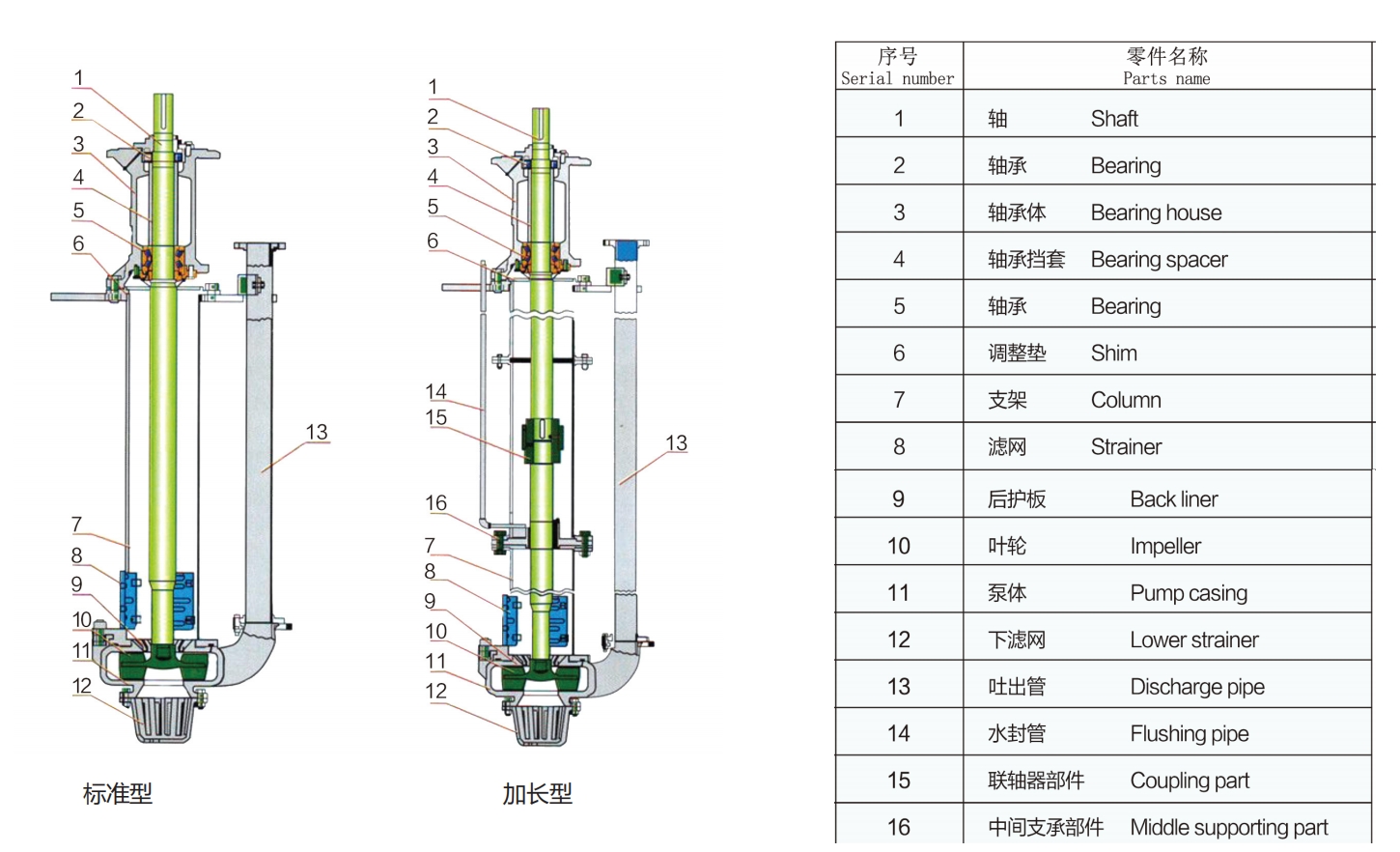

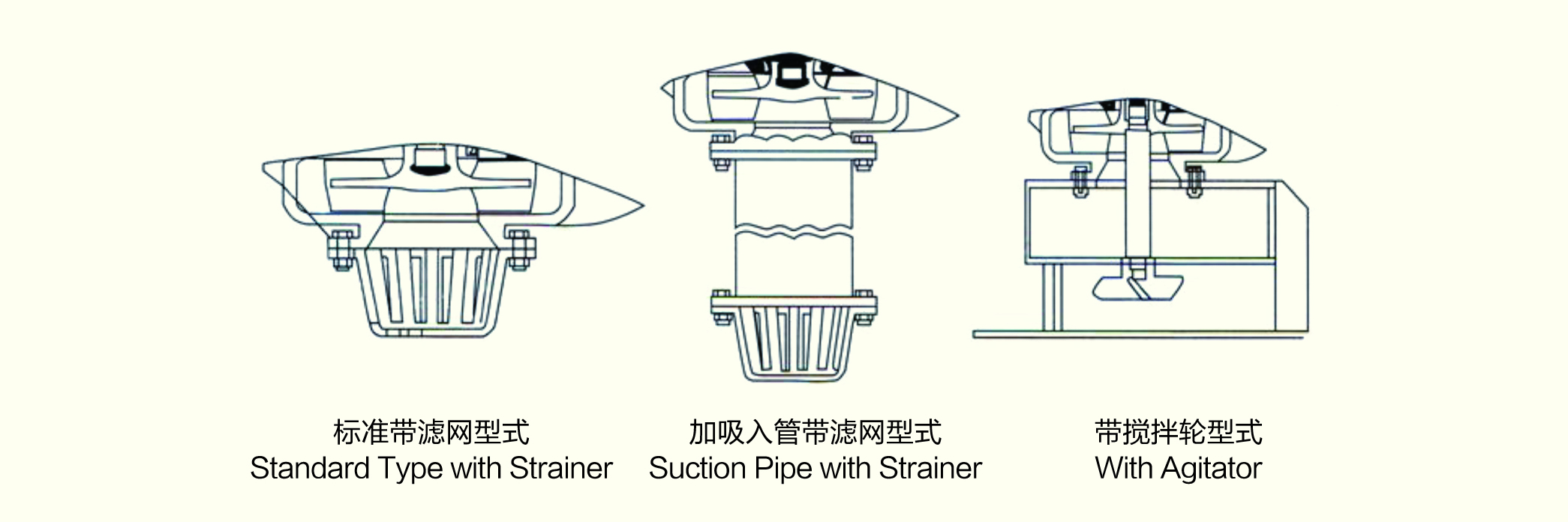

TSP series slurry pump is a single stage, single suction, cantilever, vertical centrifugal structure. It is suitable for conveying abrasive, coarse particles, and high concentration slurry without any need for shaft seal water, and can work normally even under insufficient suction conditions. This pump is particularly suitable for various pit pumps in mines and coal preparation systems.

| Model |

Matching power P (KW) |

Capacity Q (m³/h) |

Head H (m) |

Speed n (r/min) |

Eff.η (%) |

Impeller dia. (mm) |

Max.particles (mm) |

Weight (kg) |

| 40PV-TSP | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV-TSP | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| TP100RV | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV-TSP | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200SV-TSP | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250TV-TSP | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV-TSP | 22--200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

| TSP/ TSPR CLEAR WATER PERFORMANCE | ||||||||

| MODEL | MAX. POWER (KW) |

MATERIAL | Q CAPACITY | HEAD H(m) |

SPEED n(r/min) |

MAX.Eff η% |

||

| LINER | IMPEL | (m 3 /h) | (I/S) | |||||

| 40PV-TSP | 15 | M | M or RU | 19.44~43.2 | 5.4~12 | 4.5~28.5 | 1000~2200 | 40 |

| 40PV-TSPR | 15 | RU | RU | 17.28~39.6 | 4.8~11 | 4~26 | 1000~2200 | 40 |

| 65QV-TSP | 30 | M | RU | 23.4~111 | 6.5~30.8 | 5~29.5 | 700~1500 | 50 |

| 65QV-TSP | 30 | M | M | 19.8~93.06 | 5.5~25.85 | 5~29.5 | 700~1500 | 40 |

| 65QV-TSP | 30 | M | M | 23.4~87.12 | 6.75~24.2 | 5.5~31.5 | 700~1500 | 58 |

| 65QV-TSPR | 30 | RU | RU | 22.5~105 | 6.25~29.15 | 5.5~31.5 | 700~1500 | 51 |

| 65QV-TSP | 30 | M | M | 18.9~89.1 | 5.25~24.75 | 5~28 | 700~1500 | 35 |

| 100RV-TSP | 75 | M | RU | 56.7~221.76 | 15.75~61.9 | 4.5~34.5 | 500~1200 | 56 |

| 100RV-TSP | 75 | RU | RU | 64.8~285 | 18~79.2 | 7.5~36 | 600~1200 | 62 |

| 100RV-TSPR | 75 | M | M | 54~289 | 15~80.3 | 5~35 | 500~1200 | 56 |

| 100RV-TSP | 75 | M | M | 54~237.6 | 15~66 | 6~30 | 600~1200 | 40 |

| 150SV-TSP | 110 | M | RU | 108~479.16 | 30~133.1 | 8.5~40 | 500~1000 | 52 |

| 200SV-TSP | 110 | M | M or RU | 189~891 | 52.5~247.5 | 6.5~37 | 400~850 | 64 |

| 250TV-TSP | 200 | M | M or RU | 261~1089 | 72.5~302.5 | 7.5~33.5 | 400~750 | 60 |

| 300TV-TSP | 200 | M | RU | 288~1267 | 80~352 | 6.5~33 | 350~700 | 50 |

Mining and mineral processing process and spillage sump duties

Mill scale pumping in steel mills

Sugar cane processing

Non-contact induced-flow pumping of impact-sensitive media like carbon transfer or froth

(when provided with an optional recessed vortex impeller)

| ★ Minerals processing | ★ Coal preparation | ★ Chemical processing |

| ★ Effluent handling | ★ Sand and gravel | ★ Abrasive and/or corrosive slurries |

| ★ Large particle sizes | ★ High density slurries | ★ Heavy duties demanding cantilever shafts |